This sensor is ready to use; just plug it into your jFermi bioreactor over USB, and the system will automatically detect it. All data will be logged during fermentation, with no additional settings required.

Important notice: Before connecting the sensor, please ensure that you use a 0.45um hydrophobic filter and a foam trap to prevent sensor damage.

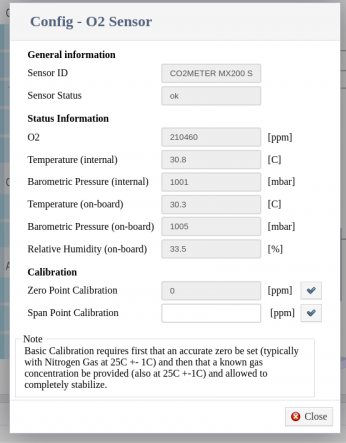

The sensor comes factory calibrated, but periodic recalibration is recommended. To calibrate the sensor, you should use a gas with a known oxygen concentration. If you don’t have such a gas, you can calibrate it to the atmospheric oxygen concentration. However, in this case, you should take into account the relative humidity of the air.

Specifications

- Measuring Gas: Oxygen

- Measurement Range: 0.1 to 25% O2

- Sensing Method: Fluorescence quenching by oxygen

- Measurement Interval: 1 Sample/second

- Response Time: < 60 Seconds

- Warm-Up Time: < 60 Seconds at 72°F (22°C)

- Accuracy: Better than 2% at full scale

- Resolution: 0.10% / 0.1mbar

- Temperature Accuracy: +/- 2 degrees C

- Operating Temperature: -30°C to +60°C

- Barometric Pressure Range: 500 to 1200 mbar

- Lifetime: > 5 years

Off-gas analysis is important in fermentation for several reasons:

- Monitoring metabolic activity: Off-gas analysis provides valuable information about the metabolic activity of the microorganisms during fermentation. By analyzing the composition and quantity of gases emitted, such as CO2 and O2, it is possible to understand the growth, respiration, and metabolic rates of the microorganisms.

- Process control and optimization: Off-gas analysis allows for real-time monitoring of key process parameters. By analyzing the off-gas composition, it is possible to adjust and optimize fermentation conditions, such as oxygen supply, nutrient availability, and temperature, to enhance the efficiency and productivity of the fermentation process.

- Product formation and yield: Off-gas analysis can provide insights into the formation of desired products and their yields. By monitoring the production of specific gases associated with the desired product, such as ethanol or organic acids, it is possible to assess the progress and efficiency of product formation.

- Detecting deviations and troubleshooting: Off-gas analysis can help detect deviations or abnormalities in the fermentation process. Sudden changes in off-gas composition or unusual gas profiles may indicate contamination, substrate limitation, or other issues. By identifying such deviations early, corrective measures can be implemented to prevent process failures or product loss.

- Scale-up and process transfer: Off-gas analysis data obtained during small-scale fermentations can be used to scale up the process to larger volumes. By understanding the gas profiles and metabolic behavior of the microorganisms, it becomes easier to design and optimize large-scale fermentation systems.

Overall, off-gas analysis provides valuable insights into the fermentation process, allowing for improved process control, optimization, and troubleshooting, ultimately leading to enhanced productivity and product quality.

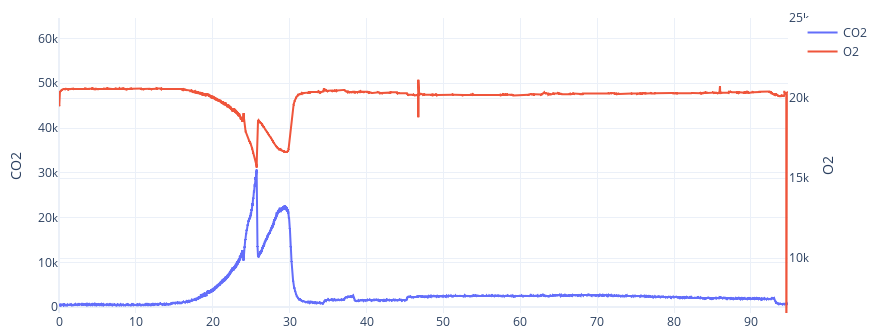

Example: Candida boidinii D-Xylitol production

In this example, the aim was to produce D-Xylitol. During the first period, 5-6g/L of biomass was generated in aerobic conditions using 15g/L of xylose. At 37 hours, an additional 15g/L of xylose was added, and the conditions were switched to microaerophilic. D-Xylitol production began at this point. This is a typical example of bioconversion. Monitoring off-gas CO2 and O2 emissions provided valuable information about cellular metabolic activity.