Peristaltic pump unit

Fig. 1: jFermi peristaltic pump

The current peristaltic pump 3D printed version was built into the first generation bioreactor prototype. It consists of PLA + (Poly lactic acid with some additives to reduce brittleness) and a mid-range 3D printer was used to create it We had doubts about the structural stability of PLA + plastics, but after months of testing, it performed well and—not least—meets the environmental standards. Of course, it is possible to install injection molded pump head units manufactured by a third party for long-term usage.

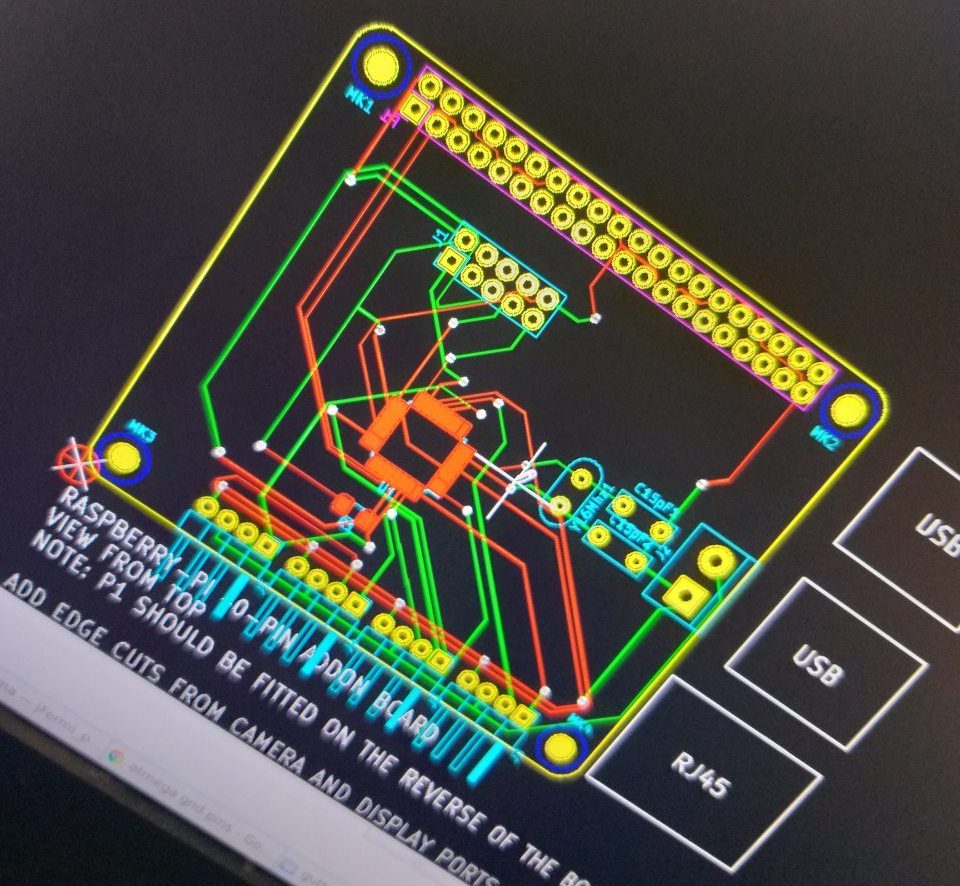

The rotor is powered by a Parallax Feedback 360 ° High Speed Servo, which is operated via a servo controller circuit produced by jFermi. The PCB, in its simplest form, carries an Atmega328pb 8-bit microcontroller that is able to control up to four Parallax servos. The circuit itself is controlled by a SoC board programmed in JavaScript.

Fig. 2: PCB, pump driver

Our strategic goal is to use JavaScript everywhere, even in MCUs. We are working hard to replace our 8bit MCUs with ARM Cortex microcontollers, thus making it possible to use JavaScript on the lowest level.

From the fermentation point of view, four peristaltic pumps have proven to be sufficient in most cases. The classic 4: acid, base, nutrient, antifoam. Each of the four pumps can be individually programmed to perform any task: timed dosing, delayed start, signal control based on pH, pO2, CO2, etc.

PID parameters are directly output to the user interface, so they can be conveniently modified at any time, even with the help of a wizard.

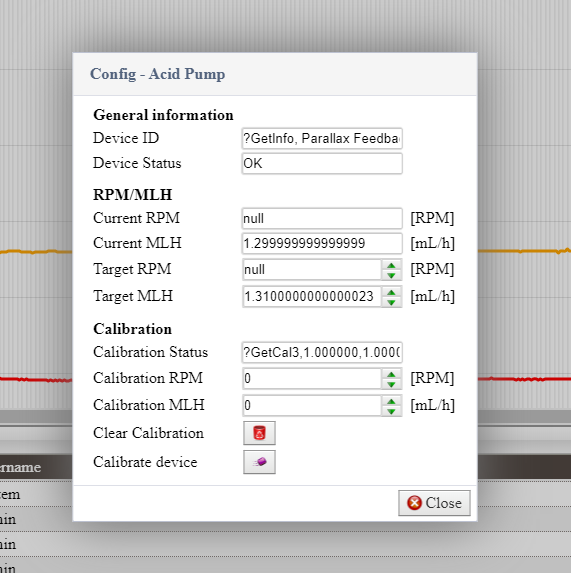

Fig. 3: Calibration panel

Performing a calibration is easy — you just need to assign an rpm value to ml/h or g/h. For a specific tubing with a constant length, the flow rate is proportional to the pump rotor speed. Therefore, the flow rate at a given rotor speed can be calibrated by measuring the total amount of liquid that is delivered in a specific time duration. To obtain the accurate amount of liquid delivered, the tubing should be completely filled with the liquid before starting the dispensing of liquid.

For example, suppose the pumping time duration is t (min), and the delivered amount of liquid is m in grams (or volume V in milliliters). Then the flow rate can be expressed as the following formula:

Mass Flow Rate = m/t (g/min)

or Volume Flow Rate = V/t (ml/min)

To perform mass flow rate calibration, the delivered liquid in time t can be dispensed in a beaker and then the net liquid mass can be weighed on a scale or a lab balance. For volume flow rate, the liquid can be dispensed to a volumetric cylinder to measure the volume after pumping.

The frequency of calibration depends mainly on the material of the hose and the properties of the fluid it delivers (dynamic viscosity (η), density (ρ)). By default, we consider the peristaltic pump head characteristic to be constant, relying on the rotary encoder and electronics.

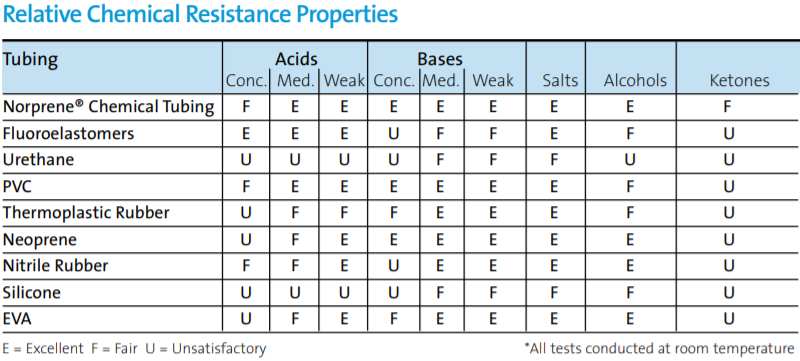

The most commonly used hose types are silicone, Norprene and Neoprene (synthetic rubber, polychloroprene). Silicone tubes are good for a lot of things, but in this case their use is based on a cost-effectiveness approach. The smaller the diameter of the hose, the sooner it will wear out. Frequently replacing hoses with an inner diameter of 0.5 mm may be worth it, because otherwise their accuracy may decline, but this also depends on many factors.

Fig. 4: https://www.usplastic.com/catalog/files/specsheets/FT-Norprene-Chemical.pdf

As shown in the table above, it is definitely not recommended to use it for acid pumping. This was also the case when 10% sulfuric acid was pumped through a 0.5 mm inner diameter tube, and after a few days the inner surface stuck together. Noroprene tubes have a lifetime at least 10 times longer and have excellent chemical resistance at a price of 30-40 Euro per meter when the above parameters are considered.

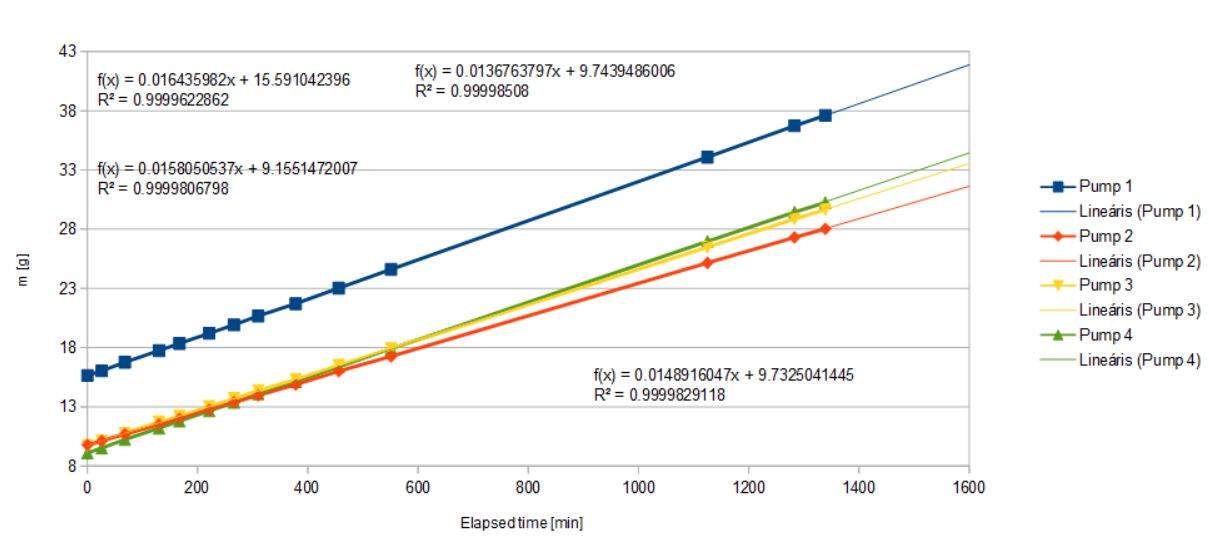

Finally, let’s look at some calibration results. In this case, we used a silicone tube with the following parameters: ∅inner = 0.5 mm, ∅outer = 2 mm, rpm = 2, d-water.

Fig. 5: Peristaltic pump calibration

Four pumps were calibrated simultaneously, and the graph shows that dosing was perfectly linear over the last 24 hours. In addition, the following feed rates could be assigned to 2 rpm.

| Average | |||

| P1 [g/h] | P2 [g/h] | P3 [g/h] | P4 [g/h] |

| 0.974 | 0.813 | 0.892 | 0.958 |

It can be seen that the values differ slightly; these are specific to each pump head, but can be reproduced perfectly at the next measurement.

Measurement result is download FROM HERE.