The collaboration has started! Two fermentation units were placed with the Department of Applied Biotechnology and Food Science Biorefinery Research Group (Budapest University of Technology and Economics’ Faculty of Chemical Technology and Biotechnology). And, the units are ready for testing. The basis of collaboration from the jFermi side is to support xylitol and enzyme producing fermentations, to provide documentation and create a database. For the future development plan this database will be used to predict changes needed for the upcoming fermentation conditions, improving the process through machine learning. On the other side, the research group, led by Dr. Csaba Fehér, will help jFermi to elaborate the theoretical background of bioprocesses and integrate them into jFermi platform.

The following article is intended as an interdisciplinary knowledge transfer between fermentation biotechnology and software engineering.

The first parameter that it should determine and integrate the automatic calculation into jFermi system is an OTR (oxygen

transfer rate). In the following, a brief summary of the OTR:

In aerobic bioprocesses, oxygen is a key substrate; due to its low solubility in broths (aqueous solutions), a continuous supply is needed. The oxygen transfer rate (OTR) must be known, and if possible predicted to achieve an optimum design operation and scale-up of bioreactors. Many studies have been conducted to enhance the efficiency of oxygen transfer. The dissolved oxygen concentration in a suspension of aerobic microorganisms depends on the rate of oxygen transfer from the gas phase to the liquid, on the rate at which oxygen is transported into the cells (where it is consumed), and on the oxygen uptake rate (OUR) by the microorganism for growth, maintenance and production.

The gas-liquid mass transfer in a bioprocess is strongly influenced by the hydrodynamic conditions in the bioreactors.

DOI: 10.1016/j.biotechadv.2008.10.006

Procedure for determination of OTR

Since the OTR value is highly dependent on the fermenter characteristics (impeller size, number, baffles), set values (mixing

speed, temperature) and nutrient composition (ion concentration, viscosity, density), it should be determined for each experiment.

Essentially, as with all fermentations, the medium is in the fermentor, also the sensors are inserted, the pH adjusted, sterilized, temperature is at desired value. This procedure takes approximately 20 minutes. Of course, this does not need to be done every time in the same fermentor using the same medium composition. The previously determined value should be available in the fermentor database and if necessarily the user must have access to it and must be able to assigne it to the new fermentation/must be able able to import the value to the new fermentation datasheet.

In a continuous stream of nitrogen, air is displaced from the culture medium, and when the oxygen concentration is achieve 0% afterward switch to air stream and start data collection. The DO level will increase slowly.

| Elapsed time [s] | DO [%] | -ln(1-DO/x) |

| 3 | 0.1 | 0.0010005003 |

| 6 | 0.1 | 0.0010005003 |

| 9 | 1.8 | 0.0181639706 |

| 12 | 1.7 | 0.0171461588 |

| 15 | 2 | 0.0202027073 |

| 18 | 2.5 | 0.025317808 |

| 21 | 3.2 | 0.0325231917 |

| 24 | 4 | 0.0408219945 |

| 27 | 5.2 | 0.0534007767 |

| 30 | 6.8 | 0.0704224643 |

Here, x represents the maximum oxygen concentration available, in this case 100%. Most often this is used, but can also be the value in mg / L, so this input field must be variable by the user. The table contains the first 30 seconds of measurement values, which is in reality more than a 1000 s which is 17 min.

Some words about oxygen solubility

The concentration of dissolved oxygen (DO) in water is influenced by a number of factors, including water temperature, salinity and atmospheric pressure. The relationship between water temperature and DO is inverse: Cold water is able to “hold” more O2 than warm water.

Basis of calculation

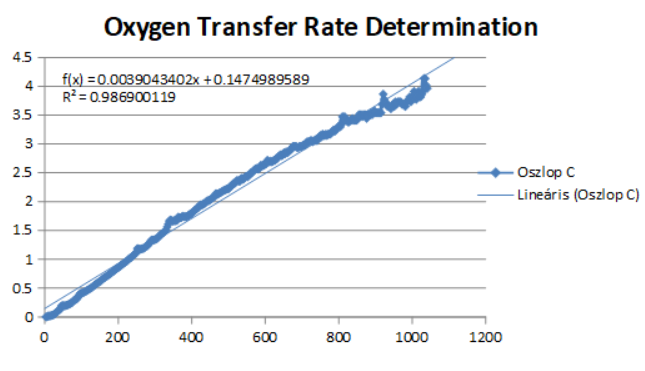

The first step is to take the negative natural logarithm of DO value, which, when plotted against time, gives a straight line with a value of R2 close to 1.

The slope of this function is the KLa – volumetric oxygen transfer coefficient [s-1]. The following submenu may open, for example, from the settings menu, where you can name and assign a fermenter and a medium composition.

| Parameters | Values | Constant for C* calc. | Values |

|---|---|---|---|

| Rotational speed [rpm] | 500 | A | 14.16 |

| Airflow [sml/min] | 200 | B | 0.3943 |

| T [°C] | 30 | C | 0.007714 |

| C* [mg/L] | 7.53 | D | 0.0000646 |

| KLa [1/s] | f(x) = | ||

| OTR [mmol/Lh] | 3.93 |

| Input fields, total: 5 pcs |

| Containing mathematical operations, total: 3 pcs |

Standard concentration of dissolved oxygen

C* = A – (B × T) + (C × T2) – (D × T3)

OTR calculation

OTR = KLa × C* × 60 × 60 /32

Measurement protocol: KLA meres

Big thanks to Soma Bedő to contribute carrying out this experiment and provide us with the mathematical relations.

Felhasznált irodalom:

- Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview.

DOI: 10.1016/j.biotechadv.2008.10.006 - Oxygen Transfer Rate Determination: Chemical, Physical and Biological Methods

DOI: 10.1002/9780470054581.eib467 - BIOMÉRNÖKI MŰVELETEK ÉS FOLYAMATOK – SEVELLA BÉLA